In recent years, laser engraving technology has gained significant popularity across various industries, from manufacturing to personal crafting. The precision, versatility, and efficiency of the laser engraving machine make it an indispensable tool for engraving intricate designs onto a wide range of materials. In fact, the printing industry is heavily adopting engraving technology, especially laser engraving.

For newbies coming into this industry, there are several things that they need to understand to get it right. First, understand the latest developments in this technology to avoid investing in obsolete tech. They also need to understand the best area of application. Selecting the right laser engraver machine is also crucial.

In this article, we’ll delve into the latest advancements in laser engraving technology, explore its diverse applications, and provide a comprehensive buying guide for newcomers looking to invest in their first laser engraving machine. But first:

What Is A Laser Engraving Machine?

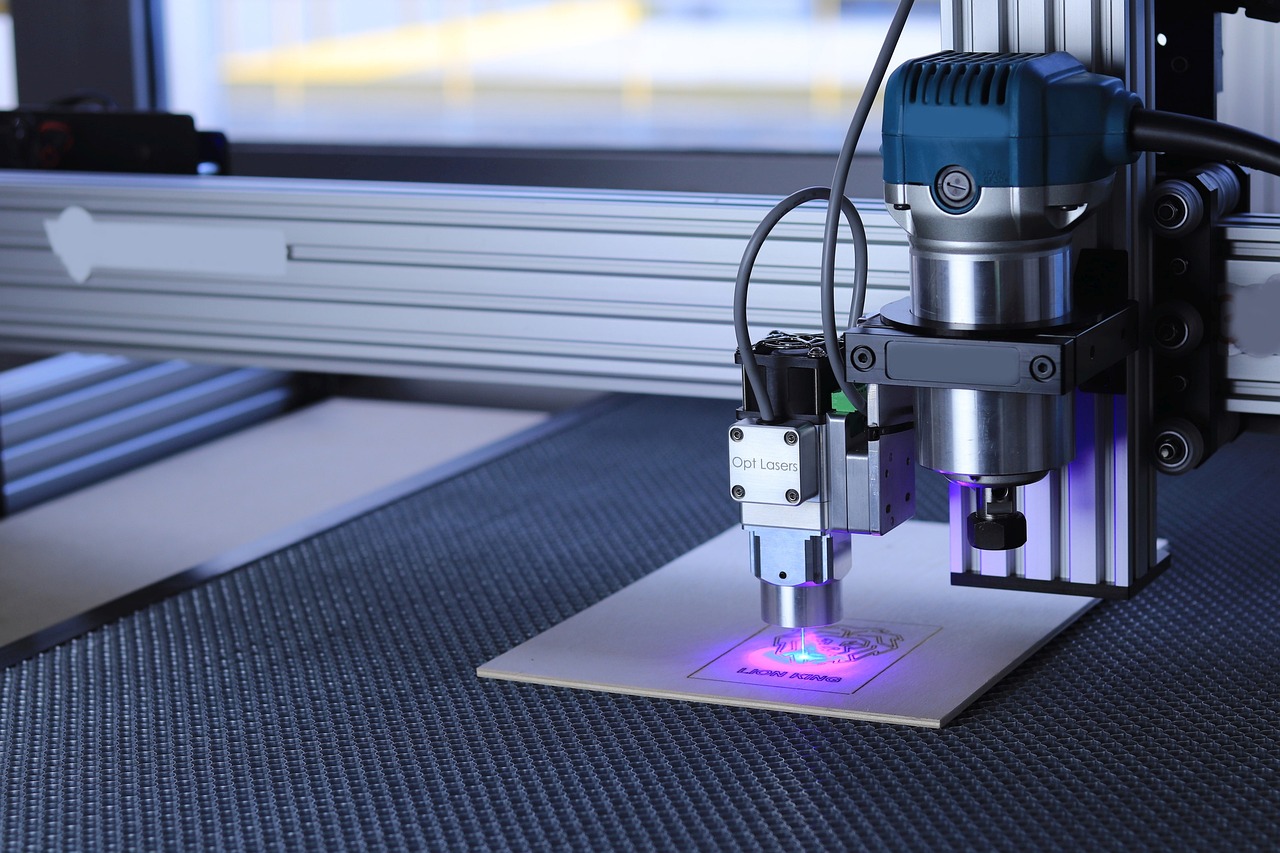

A laser engraving machine is a sophisticated tool used to etch or engrave designs, patterns, or text onto various materials with precision and accuracy. It utilizes a high-powered laser beam to remove material from the surface, creating permanent marks or designs.

These machines come in different types, including CO2 lasers, fiber lasers, and diode lasers, each suited to specific materials and applications. CO2 lasers are commonly used for engraving wood, acrylic, and glass, while fiber lasers excel at marking metals like stainless steel and aluminum. Diode lasers, on the other hand, are ideal for engraving plastics and certain metals.

Laser engraving machines are controlled by computer software, allowing for precise control over the engraving process. Users can upload digital designs or create custom artwork directly within the software, giving them complete creative freedom.

These machines find applications across various industries, including manufacturing, jewelry making, signage, and personalization. They offer numerous advantages over traditional engraving methods, including faster processing times, higher precision, and the ability to create intricate designs with ease.

In summary, a laser engraving machine is a versatile tool that utilizes laser technology to engrave designs onto various materials with precision and efficiency, making it a valuable asset for businesses and hobbyists alike.

Major Advancements in Laser Engraving Technology

Laser engraving technology has evolved considerably since its inception, with advancements continually pushing the boundaries of what’s possible. One notable development is the integration of more powerful lasers, allowing for faster engraving speeds and the ability to work on a broader range of materials. Here are key advances worth noting:

Enhanced Laser Power:

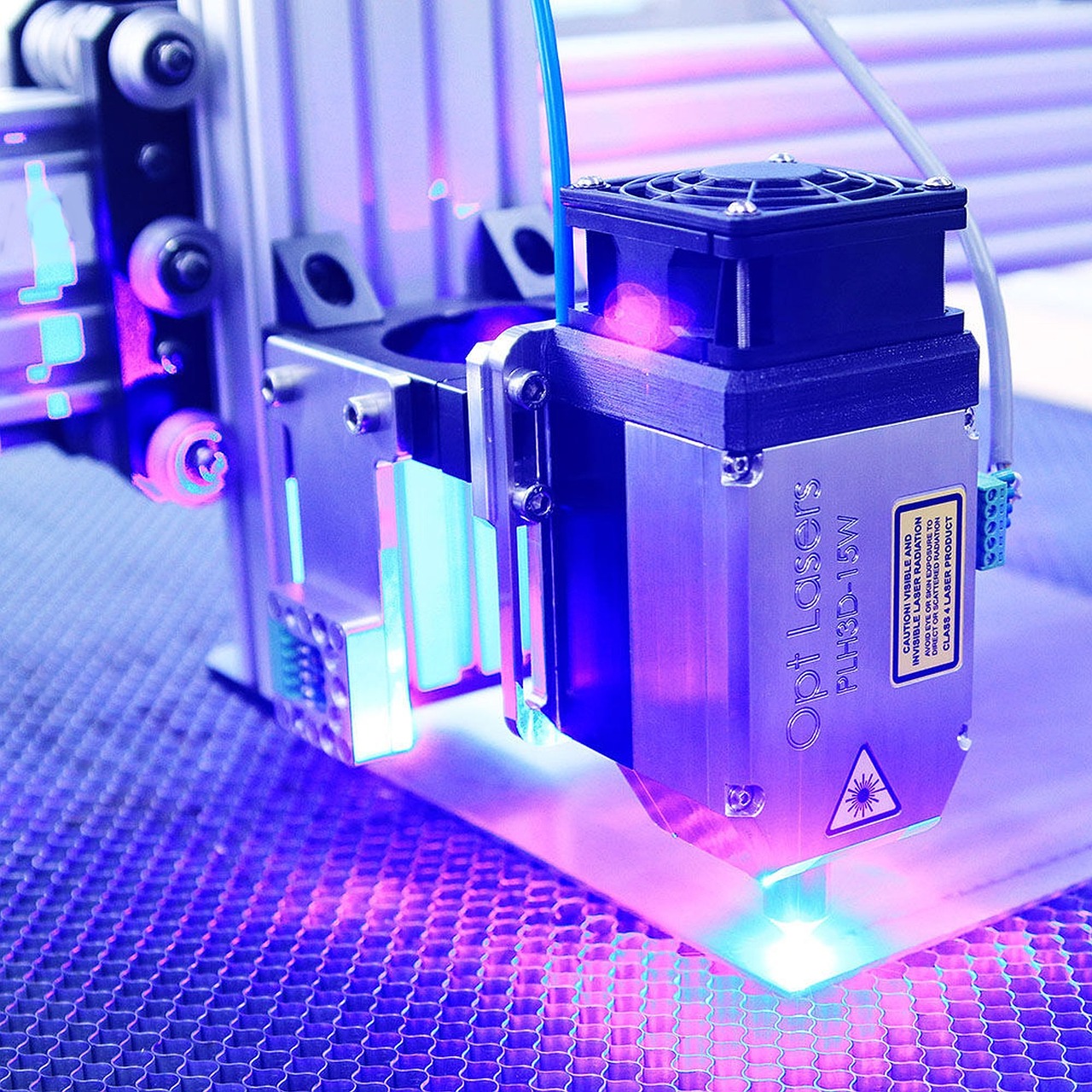

Recent advancements have witnessed the integration of more powerful lasers into engraving machines. These higher-powered lasers enable faster engraving speeds and expand the range of materials that can be engraved. By delivering increased energy density to the surface, these lasers can remove material more efficiently, resulting in shorter processing times and higher productivity.

Improved Precision and Accuracy:

Laser control systems have undergone significant improvements, enhancing the precision and accuracy of engraving. This allows for the creation of intricate designs with unparalleled detail. Advanced control algorithms ensure that the laser follows the desired path with precision, resulting in crisp, clean engravings even on the most delicate surfaces.

Compact and User-Friendly Designs:

The latest laser engraving machines feature compact designs and user-friendly interfaces, making them more accessible to both professionals and hobbyists. These machines are equipped with intuitive controls and touchscreen interfaces, simplifying the engraving process and reducing the learning curve for newcomers. Additionally, advancements in machine design have led to quieter operation and reduced maintenance requirements, further enhancing user experience.

Integration of CNC Technology:

The integration of computer numerical control (CNC) technology has revolutionized the laser engraving process. CNC systems allow for automated engraving based on digital designs, eliminating the need for manual input and ensuring consistent results. This automation streamlines production workflows and enables mass customization, catering to individual preferences and specifications with ease.

Versatile Software Integration:

Laser engraving machines now come with versatile software packages that facilitate seamless integration with design software. Users can import digital designs or create custom artwork directly within the software, providing them with complete creative freedom. These software packages also offer advanced features such as layer management, image tracing, and text editing, further expanding the possibilities for customization and creativity.

Major Applications of Laser Engraving Today

The versatility of laser engraving machines lends itself to a myriad of applications across various industries. Some common uses include:

Personalized Gifts and Keepsakes:

Laser engraving is widely used to add a personal touch to gifts and keepsakes. Whether it’s engraving names, dates, or meaningful messages onto jewelry, photo frames, or plaques, laser technology allows for precise and intricate designs that make each item unique and special. This customization enhances the sentimental value of the gift and creates a lasting impression for the recipient.

Industrial Marking and Branding:

In the manufacturing industry, laser engraving is utilized for marking and branding products and components. From serial numbers and logos to barcodes and regulatory information, laser technology ensures permanent and precise markings that withstand the rigors of industrial use. This not only facilitates traceability and quality control but also enhances brand recognition and product authentication.

Architectural and Signage:

Laser engraving plays a crucial role in creating architectural models, signage, and displays. Whether it’s engraving intricate designs onto acrylic panels for architectural features or etching logos and lettering onto metal signage, laser technology offers unmatched precision and durability. These engraved elements enhance the aesthetic appeal of buildings and spaces while providing clear and legible information to visitors and customers.

Artistic and Decorative Applications:

Artists and designers utilize laser engraving to create stunning artwork and decorative pieces. From intricate patterns and textures on wood and leather to detailed illustrations on paper and fabric, laser technology enables artists to explore new dimensions of creativity. The precision and versatility of laser engraving allow for the realization of intricate designs that would be challenging or impossible to achieve using traditional methods.

Medical and Dental Marking:

Laser engraving is essential in the medical and dental fields for marking surgical instruments, dental prosthetics, and medical devices. Laser technology ensures precise and permanent markings that comply with regulatory standards and facilitate identification and traceability. These markings play a crucial role in patient safety and quality assurance, ensuring that medical and dental products are properly tracked and authenticated.

Electronics and Semiconductor Manufacturing:

Laser engraving is integral to the production of electronic components, circuit boards, and semiconductor devices. Whether it’s marking serial numbers and specifications onto components or etching precise patterns onto circuit boards, laser technology offers unmatched precision and efficiency. These markings facilitate component identification, quality control, and traceability throughout the manufacturing process, ensuring the reliability and performance of electronic products.

Best Newbie Laser Engraver Buying Guide

For those considering investing in a laser engraving machine for the first time, several factors should be taken into account:

Consider Laser Type:

When purchasing your first laser engraving machine, consider the type of laser it employs. CO2 lasers are suitable for engraving wood, acrylic, and glass, while fiber lasers excel at marking metals like stainless steel and aluminum. Diode lasers are ideal for engraving plastics and certain metals. Choose a laser type based on the materials you plan to work with and the applications you intend to pursue.

Evaluate Engraving Area:

Determine the size of the engraving area required for your projects. Smaller machines are suitable for hobbyists and small-scale production, while larger machines are necessary for industrial applications. Consider the maximum dimensions of the materials you plan to engrave and choose a machine with an appropriate engraving area to accommodate your needs.

Assess Power and Speed:

Consider the power and speed capabilities of the laser engraving machine. Higher laser power allows for faster engraving speeds and the ability to work on thicker materials. However, higher power typically comes at a higher cost, so it’s essential to strike a balance between power and budget. Evaluate your production requirements and choose a machine with sufficient power and speed to meet your needs.

Check Software Compatibility:

Ensure that the laser engraving machine is compatible with the design software you plan to use. Most machines come with proprietary software, but some also offer compatibility with third-party programs for added flexibility. Consider the features and capabilities of the software package included with the machine and ensure that it meets your design and workflow requirements.

Consider Ease of Use:

Look for a laser engraving machine that is user-friendly and intuitive, especially if you’re a beginner. Features such as touchscreen interfaces, automatic focus adjustment, and pre-set material settings can streamline the engraving process and reduce the learning curve. Choose a machine with an intuitive interface and comprehensive user manual to help you get started quickly and easily.

Evaluate Maintenance and Support:

Consider the maintenance requirements of the machine and the availability of technical support and spare parts. Opt for a reputable manufacturer with a track record of reliability and customer satisfaction. Look for a machine with easy access to critical components and clear maintenance instructions to ensure smooth operation and minimize downtime.

Prioritize Safety Features:

Laser engraving machines emit high-intensity laser beams, so it’s crucial to prioritize safety features such as enclosure systems, emergency stop buttons, and interlock mechanisms to prevent accidents and ensure operator safety. Choose a machine with robust safety features and follow all recommended safety guidelines and procedures to protect yourself and others while operating the machine.

Conclusion

Laser engraving technology continues to push the boundaries of creativity and innovation, with its precision, versatility, and efficiency making it a valuable tool across various industries. Whether you’re a hobbyist, entrepreneur, or manufacturer, investing in a laser engraving machine opens up a world of possibilities for customization, branding, and creative expression. With the latest advancements in technology and a comprehensive understanding of its applications and buying considerations, newcomers can embark on their laser engraving journey with confidence and enthusiasm.