Laser engraving technology has revolutionized the way we personalize and create intricate designs on various materials, from wood and acrylic to metal and glass. The technology is quickly being adopted in the printing industry as well as in beauty. Today, people are getting tattooed using laser engraver machines.

As the demand for customized products continues to rise, the market for laser engraver machines has expanded, offering a wide range of options for businesses and hobbyists alike. In this article, we will explore the world of laser engraver machines, covering manufacturers’ selection tips, essential factors to consider when buying, and tips for maintenance to ensure optimal performance and longevity.

But before that, let’s have a look at what a laser engraving machine is.

What Is a Laser Engraver Machine?

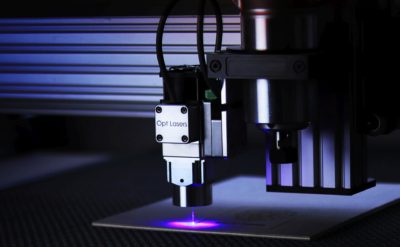

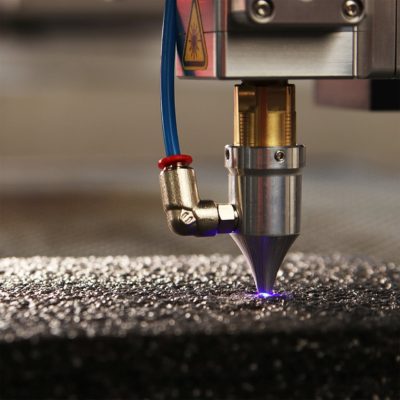

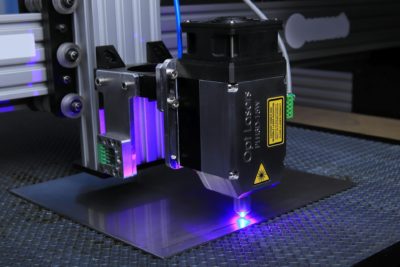

A laser engraver machine is a versatile tool that utilizes laser technology to etch designs, patterns, text, and images onto various materials. It does this with precision and detail. At its core, the machine consists of a laser beam emitted from a high-powered laser source, typically a CO2 or fiber laser. The laser beam is directed onto the surface of the material to be engraved.

The laser beam is controlled by sophisticated software, allowing users to create intricate designs and adjust settings such as power, speed, and focus to achieve desired results. The material absorbs the intense heat generated by the laser, causing it to vaporize or change color. This results in permanent markings or engravings. These engravings can be used in printing and other processes.

Laser engraver machines come in a variety of sizes and configurations, ranging from compact desktop models suitable for small-scale projects to large-format industrial machines capable of engraving on oversized materials. They can engrave on a wide range of substrates, including wood, acrylic, glass, metal, leather, and plastic, making them invaluable tools for industries such as manufacturing, signage, jewelry, and personalized gifts.

Overall, laser engraver machines offer unparalleled precision, efficiency, and versatility, making them essential equipment for businesses, artisans, and hobbyists alike seeking to add custom designs and personalization to their products.

7 Key Things To Look For In Laser Engraver Manufacturers:

Laser engraving technology has transformed the customization and design industries, offering intricate detailing on various materials with precision and speed. With numerous manufacturers in the market, choosing the right one becomes crucial for achieving optimal results. Let’s delve into the essential factors to consider when evaluating laser engraver machine manufacturers.

Reputation and Reliability:

Prioritize manufacturers with a solid reputation for producing high-quality and reliable laser engraving machines. Research customer reviews, testimonials, and industry awards to gauge their reputation and track record of customer satisfaction.

Technology and Innovation:

Look for manufacturers at the forefront of technological advancements in laser engraving technology. Companies that invest in research and development to improve machine performance, efficiency, and versatility are more likely to offer cutting-edge solutions tailored to your needs.

Product Range and Customization Options:

Assess the manufacturer’s product portfolio to ensure they offer a diverse range of laser engraving machines suitable for various applications and industries. Additionally, inquire about customization options to tailor the machine specifications to your specific requirements.

Quality Assurance and Compliance:

Verify that the manufacturer adheres to stringent quality control standards and regulatory compliance in the design, manufacturing, and testing of their laser engraving machines. Certifications such as ISO 9001 and CE mark signify adherence to quality management and safety standards.

Technical Support and Training:

Choose a manufacturer that provides comprehensive technical support, training, and resources to assist you in the setup, operation, and maintenance of your laser engraver machine. Access to troubleshooting guides, online forums, and expert assistance can significantly enhance your user experience.

After-Sales Service and Warranty:

Evaluate the manufacturer’s after-sales service policies, including warranty coverage, repair services, and spare parts availability. A robust warranty package and responsive customer support ensure peace of mind and prompt resolution of any issues that may arise during the machine’s lifespan.

Sustainability and Environmental Responsibility:

Consider manufacturers committed to sustainable practices and environmental responsibility in their manufacturing processes and product design. Look for energy-efficient machines, eco-friendly materials, and responsible waste management practices to minimize your ecological footprint.

Buyers Best Tips When Buying Laser Engraving Machines

Most buyers going to the market for the first time make a lot of mistakes when selecting these machines. What are the key factors to be considered when making a purchase? Well, there are basic things that a good engraving machine should have. Here are just some of the factors that warrant consideration to ensure an informed purchase decision:

Material Compatibility:

Beyond standard substrates, assess the machine’s ability to engrave specialized materials like ceramics, stone, or even cylindrical objects. Compatibility with a diverse range of materials expands creative possibilities and widens the scope of potential applications, catering to various industries and artistic pursuits.

Precision and Resolution:

Investigate the machine’s precision capabilities, measured in terms of spot size and beam quality. Higher precision and resolution levels ensure crisp, detailed engravings, crucial for intricate designs and intricate patterns. This level of precision is particularly valuable for industries requiring fine detailing, such as jewelry making, electronics, or medical device manufacturing.

Cooling System:

A robust cooling system is essential for maintaining optimal performance, especially in high-power laser engraver machines. Efficient cooling mechanisms, such as water or air cooling systems, prevent overheating during prolonged operation sessions, ensuring consistent engraving quality and prolonging the lifespan of critical components like the laser tube and optics.

Support and Training:

Access to comprehensive support and training resources from the manufacturer is invaluable, particularly for users new to laser engraving technology. Technical assistance, online tutorials, and user manuals facilitate seamless setup, operation, and troubleshooting, empowering users to maximize the machine’s capabilities and achieve optimal results with confidence.

Upgradability:

Future-proof your investment by choosing a machine with upgradability options. Modular designs or compatibility with accessory upgrades allow for scalability, enabling businesses to adapt to evolving needs and technological advancements without the need for a complete machine replacement. This flexibility ensures long-term value and efficiency in the face of changing market demands.

Portability and Space Considerations:

For small businesses or hobbyists with limited space, prioritize machines with compact designs or mobile options. Portability and a small footprint maximize space utilization and offer flexibility in workspace arrangements. It also allows users to operate the machine in various environments without compromising performance or functionality.

Integration with Existing Workflows:

Seamless integration with existing workflows is essential for maintaining productivity and efficiency. Compatibility with common design software, peripherals, and production equipment minimizes workflow disruptions and streamlines the transition to incorporating laser engraving technology into existing processes. This interoperability ensures a smooth and efficient operation from setup to production.

Laser Engraver Maintenance Guide:

Proper maintenance is essential to keep your laser engraver machine in optimal condition and prolong its lifespan. It also plays a critical role in maximizing your profits as the machine can hit optimal performance. Here are some maintenance tips to follow:

Regular Cleaning:

Establish a routine for cleaning critical components like the laser lens, mirrors, and engraving bed to remove dust, debris, and residue. Regular cleaning not only ensures optimal engraving quality but also prevents the accumulation of contaminants. These components can affect laser performance and compromise the results they accumulate over time.

Alignment Checks:

Periodically check and adjust the alignment of the laser beam to maintain precision and accuracy in engraving. Misaligned optics can result in distorted or uneven engravings, necessitating regular calibration to ensure consistent and reliable performance across various materials and projects.

Lubrication Maintenance:

Proper lubrication of moving parts and bearings is essential for smooth operation and prolonged lifespan of the machine. Follow manufacturer guidelines for lubrication intervals and use recommended lubricants to prevent friction, reduce wear, and ensure consistent performance without compromising engraving quality.

Ventilation Management:

Maintain adequate ventilation in the workspace to remove smoke, fumes, and airborne particles generated during the engraving process. Proper ventilation ensures a safe working environment for operators. But, also prevents the buildup of debris that can obstruct laser optics and affect engraving quality over time.

Component Inspection:

Regularly inspect key components such as belts, pulleys, and laser tubes for signs of wear, damage, or degradation. Replace worn or damaged parts promptly to prevent unexpected breakdowns and downtime, prolonging the machine’s lifespan and minimizing maintenance costs in the long run.

Software Updates:

Stay up-to-date with software updates and firmware upgrades provided by the manufacturer. These updates often include performance improvements, bug fixes, and new features that enhance engraving quality. They also optimize workflow efficiency, and ensure compatibility with the latest design software and operating systems.

Training and Education:

Invest in training for yourself and your staff to learn proper maintenance procedures, safety protocols, and troubleshooting techniques. Properly trained personnel can identify and address maintenance issues proactively. This minimizes downtime, maximizes productivity, and extends the lifespan of your laser engraver machine.

Conclusion

Investing in a laser engraver machine can open up endless possibilities for creativity and customization in various industries. By choosing the right manufacturer, considering important factors during the buying process, and implementing proper maintenance practices, you can ensure smooth operation and optimal performance of your machine for years to come. Whether you’re a small business owner, artisan, or hobbyist, a laser engraver machine can be a valuable asset in bringing your ideas to life with precision and efficiency.