Hot forged drilling wear parts play a crucial role in the efficiency and effectiveness of drilling operations across various industries. For beginners entering the market, navigating the plethora of options available can be daunting. This article aims to provide comprehensive buying tips for novice purchasers of hot forged drilling wear parts.

We will also explore the advantages of sourcing these parts from China. What is hot forging? These are just some of the key areas of interest that we have covered. Keep reading to understand key factors that will enable you to buy the right wear parts for your machine:

Understanding Hot Forged Drilling Wear Parts:

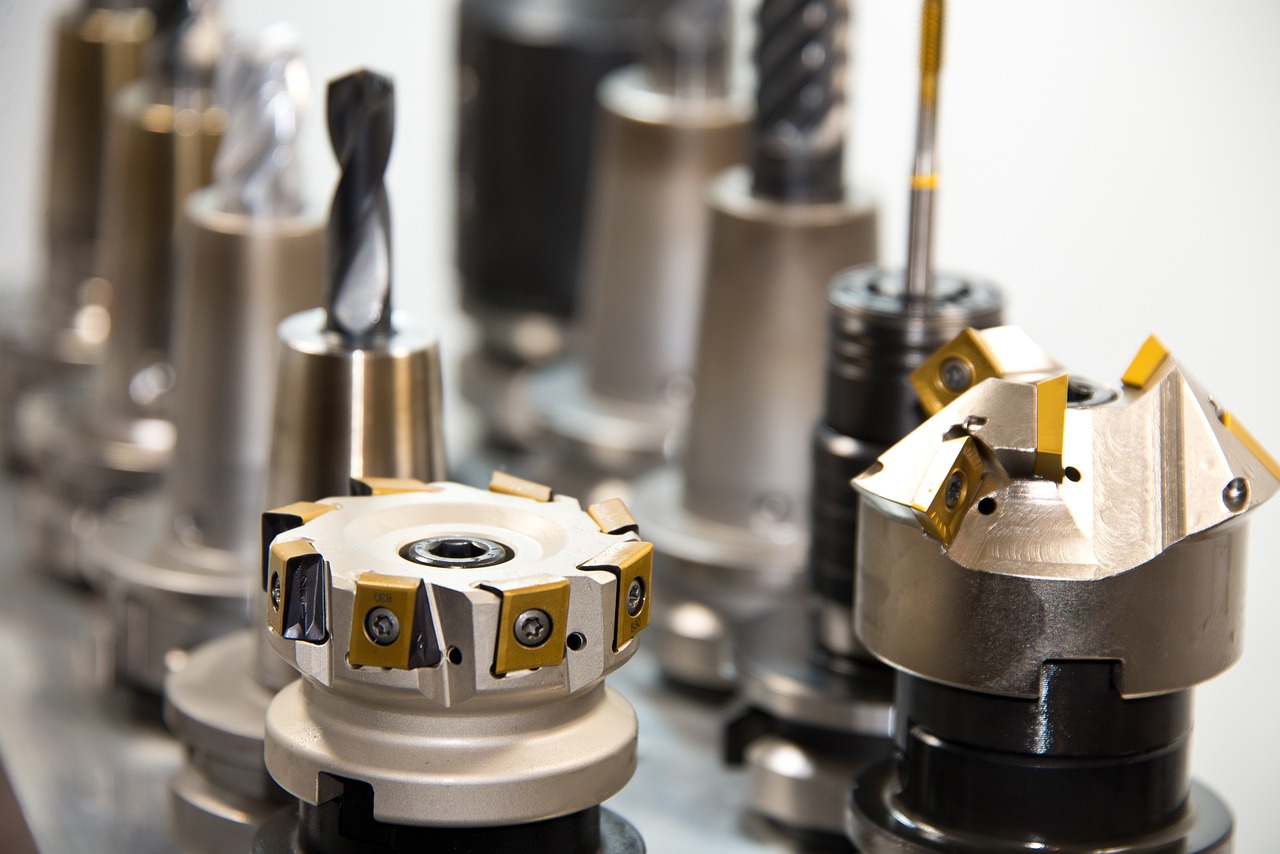

Hot forged drilling wear parts are integral components of drilling equipment, essential for various industries such as construction, mining, oil and gas, and infrastructure development. These parts undergo a specialized manufacturing process known as hot forging. Hot forging is a manufacturing process where metal is heated and shaped into desired forms through the application of pressure. This process enhances the durability, strength, and wear resistance of the wear parts, making them capable of withstanding the harsh conditions encountered during drilling operations.

Common types of hot forged drilling wear parts include drill bits, augers, cutting teeth, and adapters, each designed to perform specific functions in different drilling applications. The materials used in hot forging are carefully selected based on their mechanical properties, with high-quality steel alloys like tungsten carbide being preferred for their exceptional hardness and abrasion resistance.

The significance of hot forged drilling wear parts cannot be overstated, as they directly influence the efficiency, productivity, and longevity of drilling machinery. By understanding the characteristics and applications of these wear parts, operators can make informed decisions regarding their selection, maintenance, and replacement, ultimately maximizing the performance and cost-effectiveness of their drilling operations.

Beginner’s Buying Tips for Hot Forged Drilling Wear Parts:

Navigating the realm of hot forged drilling wear parts can be overwhelming for beginners, but armed with the right knowledge, purchasing decisions become more manageable. In this section, we explore essential buying tips tailored specifically for novices entering the market. From prioritizing quality over price to ensuring compatibility and fit with drilling equipment, these tips lay the groundwork for informed decision-making.

By understanding the importance of material selection, the reputation of suppliers, and conducting cost-benefit analyses, beginners can navigate the purchasing process with confidence, ultimately optimizing drilling performance and minimizing operational costs.

Quality Over Price:

One of the most critical tips for beginners is to prioritize quality over price when purchasing hot forged drilling wear parts. While it may be tempting to opt for cheaper options, investing in high-quality parts can significantly improve drilling performance and reduce overall maintenance costs in the long run. Quality parts are more durable, resistant to wear, and ensure smoother drilling operations, leading to increased productivity.

Compatibility and Fit:

Another crucial consideration is ensuring compatibility and proper fit of the wear parts with the drilling equipment. Before making a purchase, beginners should carefully assess the specifications and requirements of their drilling machinery and select wear parts that match these specifications precisely. Ill-fitting parts can cause inefficiencies, premature wear, and potential damage to the equipment, resulting in costly repairs and downtime.

Material Selection:

The material used in hot forged drilling wear parts plays a vital role in their performance and longevity. Common materials include high-quality steel alloys such as tungsten carbide, which offer exceptional hardness, strength, and resistance to abrasion. Beginners should research different materials and select ones that are suitable for the specific drilling applications and environmental conditions they will encounter.

Reputation and Reliability of Suppliers:

When purchasing hot forged drilling wear parts, beginners should prioritize reputable and reliable suppliers with a track record of delivering quality products and excellent customer service. Reading customer reviews, seeking recommendations from industry peers, and conducting thorough research on potential suppliers can help ensure a positive purchasing experience and reliable performance of the wear parts.

Cost-Benefit Analysis:

While quality is paramount, beginners should also conduct a cost-benefit analysis to evaluate the overall value proposition of different wear part options. This analysis should consider factors such as initial purchase price, expected lifespan, maintenance requirements, and potential productivity gains. By weighing these factors against the upfront cost, beginners can make informed decisions that optimize both performance and cost-effectiveness.

Advantages of Buying Hot Forged Drilling Wear Parts from China:

Sourcing hot forged drilling wear parts from China presents numerous advantages for buyers worldwide. With advanced manufacturing capabilities, cost-competitiveness, and a diverse product range, Chinese suppliers offer compelling solutions for enhancing drilling operations. From customized options to efficient international trade infrastructure, the benefits of buying from China extend beyond affordability.

This section delves into these advantages, shedding light on why China has become a preferred destination for procuring high-quality wear parts that optimize drilling performance and maximize operational efficiency

Advanced Manufacturing Capabilities:

China has emerged as a global leader in manufacturing, boasting advanced facilities equipped with state-of-the-art technology and machinery for hot forging and producing precision-engineered wear parts. Chinese manufacturers adhere to strict quality control standards and employ skilled technicians and engineers to ensure the highest levels of product quality and consistency.

Cost-Competitiveness:

One of the primary reasons buyers choose to source hot forged drilling wear parts from China is the cost-competitiveness offered by Chinese manufacturers. Due to lower labor and production costs compared to many Western countries, Chinese suppliers can offer competitive pricing without compromising on quality. This cost advantage enables buyers to access high-quality wear parts at affordable rates, resulting in significant cost savings over time.

Diverse Product Range:

Chinese manufacturers offer a diverse range of hot forged drilling wear parts to cater to various drilling applications and equipment types. Whether buyers require drill bits, augers, cutting teeth, or other wear components, they can find an extensive selection of options tailored to their specific needs and preferences. This diversity allows buyers to choose parts that best suit their equipment and operational requirements, enhancing overall performance and efficiency.

Customization Options:

Chinese manufacturers are known for their flexibility and willingness to accommodate custom orders and specifications from buyers. Whether it’s customizing the design, dimensions, materials, or surface treatments of wear parts, Chinese suppliers can work closely with buyers to deliver tailor-made solutions that meet their unique requirements. This customization capability enables buyers to optimize the performance and longevity of their drilling equipment while addressing specific challenges or preferences.

International Trade Infrastructure:

China’s robust international trade infrastructure and logistics networks facilitate smooth and efficient delivery of hot forged drilling wear parts to buyers worldwide. With established shipping routes, efficient customs clearance processes, and reliable freight forwarding services, buyers can expect timely and hassle-free delivery of their orders, regardless of their location. This logistical advantage further enhances the appeal of sourcing wear parts from China for buyers operating in diverse global markets.

Conclusion:

In conclusion, purchasing hot forged drilling wear parts can be a complex process for beginners, but following the right buying tips can help navigate this process with confidence and success. Prioritizing quality, compatibility, and reputable suppliers is essential for optimizing drilling performance and minimizing downtime and maintenance costs. Additionally, sourcing wear parts from China offers various advantages, including advanced manufacturing capabilities, cost-competitiveness, diverse product range, customization options, and efficient international trade infrastructure. By leveraging these benefits, buyers can access high-quality wear parts that enhance the efficiency, reliability, and profitability of their drilling operations.