CNC machines have become popular in manufacturing and other industries mainly because of their versatility and enhanced end-product quality. If you are planning to buy a China CNC machine, there are several things that you need to consider. This is what this buyers’ guide provides. But first, let’s start with understanding what a CNC machine is and its major applications.

What Is A CNC Machine

A CNC (Computer Numerical Control) machine is a computerized manufacturing tool that utilizes computer programming to control and operate various machining operations. It replaces traditional manual control methods with automated processes, allowing for precise and efficient production of complex parts and components. CNC machines are widely used across various industries due to their versatility, accuracy, and ability to automate repetitive tasks.

5 Major Applications Of A CNC Machine

There are so many emerging areas where CNC machines are useful based on types. Here are some of the 5 major types of CNC machines and their applications:

CNC Milling Machine:

CNC milling machines are used to remove material from a workpiece by rotating a cutting tool against it. They are ideal for creating intricate shapes, contours, and holes in metal, wood, plastic, and other materials. CNC milling machines are widely used in aerospace, automotive, electronics, and prototyping industries.

CNC Lathe Machine:

The CNC lathe machine produces cylindrical parts by rotating a workpiece against a stationary cutting tool. They are commonly used for turning, facing, drilling, and threading operations. CNC lathe machines are used in manufacturing, metalworking, and precision engineering industries for producing shafts, bolts, bushings, and other cylindrical components.

CNC Router:

The CNC router specialises in milling machines for cutting, carving, and engraving materials such as wood, plastic, foam, and composites. They are widely used in woodworking, sign-making, cabinetry, furniture manufacturing, and prototyping for creating intricate designs, decorative patterns, and three-dimensional shapes.

CNC Plasma Cutter:

CNC plasma cutters use a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials such as steel, aluminium, brass, and copper. They are commonly used in metal fabrication, construction, automotive, and industrial manufacturing for cutting sheet metal, pipes, and structural components with precision and speed.

CNC Laser Cutter:

CNC laser cutters use a high-powered laser beam to cut, engrave, and mark various materials, including metal, plastic, wood, glass, and fabric. They are widely used in industries such as signage, jewelry making, aerospace, medical device manufacturing, and architectural modelling for precise cutting, etching, and engraving of intricate designs and patterns.

CNC Grinding Machine:

CNC grinding machines are used for precision grinding operations to achieve tight tolerances and surface finishes on workpieces. They are commonly used in tool and die making, automotive, aerospace, and medical device manufacturing for grinding surfaces, cylindrical shapes, and complex profiles on metal, ceramics, and composites.

What Look For In CNC A Machine – 7 Tips

For a perfect China CNC machine, you need to consider these 7 factors. These are factors that will help you source the best Chinese CNC machine manufacturers and get the best quality the China market can offer. They include:

Research and Compare Brands:

Start by researching different China CNC machine brands and manufacturers. Look for reputable China CNC manufacturers with a reputation for producing high-quality machines. Compare specifications, features, and customer reviews to narrow down your options. The best Chinese CNC machine manufacturer has positive reviews from prior customers.

Define Your Requirements:

Before you start shopping for a China CNC machine, clearly define your requirements and objectives. Consider factors such as the size of the parts you’ll be machining, the materials you’ll be working with, and the level of precision and speed you need. This will help you determine the appropriate machine size, configuration, capabilities and other features. The machine should match your needs.

Evaluate Machine Specifications:

Pay close attention to the specs of each China CNC machine you’re considering. Look at parameters such as spindle speed, cutting capacity, axis travel, accuracy, and repeatability. Make sure the machine can handle the types of projects you’ll be working on and meet your performance expectations. It is also advisable to look into your business’s future needs when buying these machines.

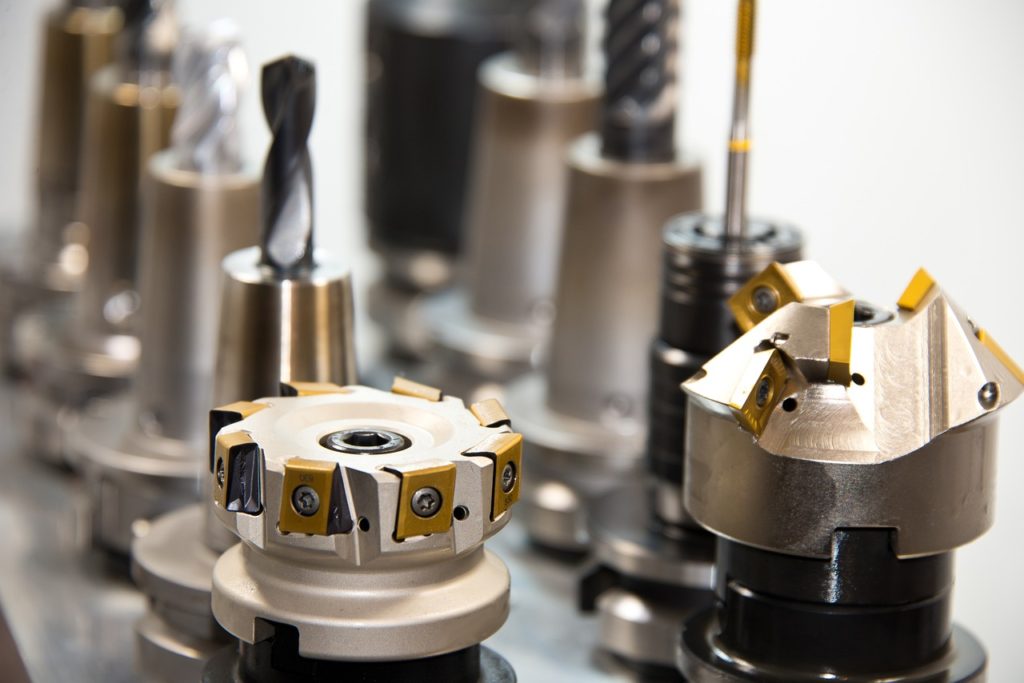

Inspect Build Quality and Components:

When possible, inspect the build quality and components of the CNC machine in person or through detailed documentation and images. Check for sturdy construction, high-quality materials, and precision machining of critical components like the spindle, linear guides, and ball screws. Look for signs of durability and reliability that indicate the machine will withstand long hours of operation. That’s how you ensure that you are getting value or money. Do not fall for cheaper offers, as there might be a compromise in quality.

Consider After-Sales Support:

Reliable after-sales support is crucial when buying a China CNC machine, especially when importing from overseas. Choose a CNC China manufacturer or supplier that offers comprehensive technical support, training, and warranty coverage. So, verify the availability of spare parts and service technicians in your region to ensure timely assistance in case of maintenance or repairs. You don’t want your machine to stall immediately after buying due to a lack of technical support.

Factor in Total Cost of Ownership:

While the upfront cost of a CNC machine is important, don’t overlook the total cost of ownership over its lifespan. Consider expenses such as installation, training, maintenance, energy consumption, and potential upgrades or repairs. Calculate the long-term return on investment (ROI) based on productivity gains and cost savings to make an informed decision. Sometimes, the cost might be unrealistically high. Therefore, shop for the best deal that benefits your business.

Seek Recommendations and Expert Advice:

Before finalizing your purchase, seek recommendations from industry peers, CNC machinists, and experts with experience with Chinese CNC machines. They can provide valuable insights, tips, and recommendations based on their firsthand knowledge and experiences. Take advantage of online forums, professional networks, and trade shows to connect with knowledgeable individuals and gather valuable information. This is important if you are a first-time buyer.

In conclusion, buying a CNC machine shouldn’t be difficult, even for newbies. So, if you carefully follow these tips, you will get the best deals in the Chinese market. The bottom line is, don’t compromise on quality.