Chinese manufacturing has undergone significant transformations in recent years, dispelling previous concerns about the quality of products, including forestry machines. The forestry industry, in particular, has witnessed a surge in the production of high-quality equipment from China. In this article, we explore five compelling reasons why the quality of Chinese-manufactured forestry machines is no longer a major concern.

Adherence to International Standards

Chinese manufacturers have made substantial investments in aligning their production processes with international standards. Forestry machines produced in China often carry certifications such as ISO (International Organization for Standardization) and CE (Conformité Européene), demonstrating compliance with rigorous quality benchmarks. These certifications serve as a testament to the commitment of Chinese manufacturers to meet and exceed global quality standards.

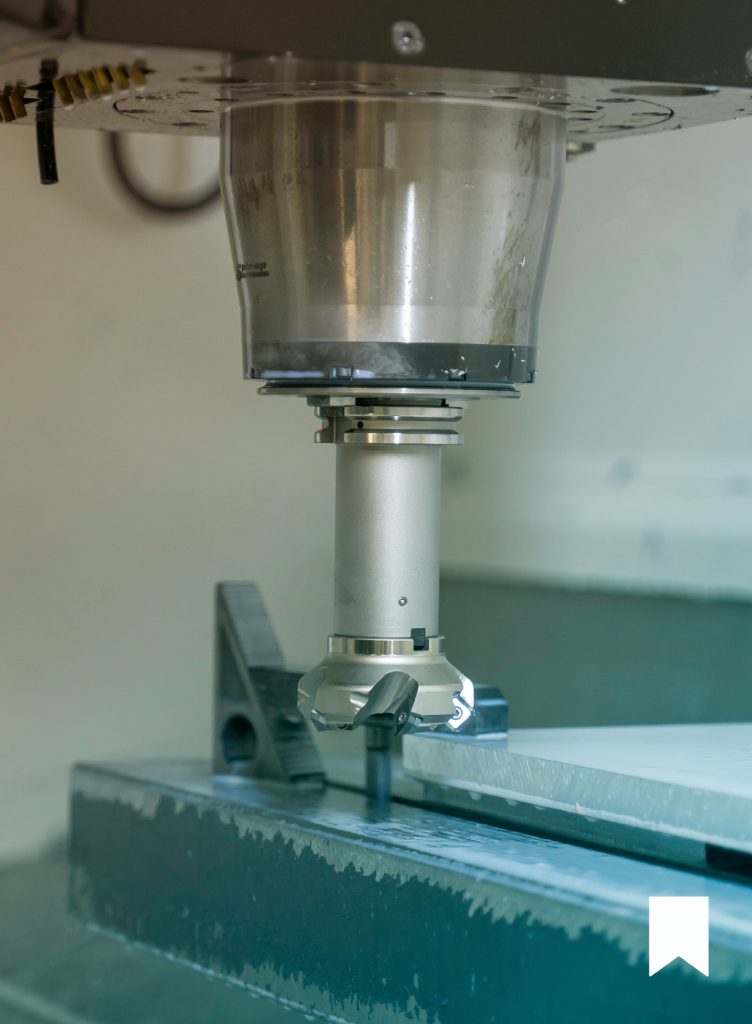

Advanced Manufacturing Technologies

China has embraced advanced manufacturing technologies, incorporating innovations in the production of forestry machines. The adoption of cutting-edge technologies enhances precision, efficiency, and overall performance. With the integration of automation, robotics, and sophisticated control systems, Chinese manufacturers can deliver pieces of equipment that not only meet but often surpass industry expectations in terms of quality.

Quality Control Processes

Stringent quality control processes are implemented throughout the manufacturing journey of forestry machines in China. From raw material inspections to the final assembly, manufacturers adhere to comprehensive quality checks at every stage. These measures ensure that each component meets specified standards, contributing to the production of machines that are reliable, durable, and capable of withstanding the demands of various forestry applications.

Investment in Research and Development

Chinese manufacturers recognize the importance of staying at the forefront of technological advancements and industry trends. Robust investments in research and development (R&D) initiatives contribute to the continuous improvement of forestry machines. By staying ahead of the curve, Chinese manufacturers can introduce innovative features, enhance product reliability, and address specific challenges faced by forestry businesses.

Efficient Communication

The open communication channels between Chinese manufacturers and their international clients have played a pivotal role in addressing quality concerns. Manufacturers actively seek feedback from customers, fostering a collaborative environment that allows for continuous improvement. Transparent communication ensures that any issues are promptly identified and resolved, contributing to a positive feedback loop that enhances the overall quality of forestry machines.

Conclusion:

The landscape of Chinese manufacturing, especially in the forestry machinery sector, has evolved significantly, erasing concerns about product quality. Adherence to international standards, incorporation of advanced technologies, stringent quality control processes, investment in research and development, and transparent communication with customers collectively contribute to the assurance of high-quality forestry machines from China. Businesses in the forestry industry can confidently explore Chinese-manufactured options, knowing that they are investing in equipment that meets or exceeds global quality benchmarks.